Hybrid Solar Drier and Wireless Communication for Efficient Seaweed Drying System to Preserve the Quality

Dr. Majid Khan Majahar Ali

Dr. Mohana Sundaram Muthuvalu

Prof. Madya Dr. Mohd Tahir Ismail

Dr. Vigneswaran Ramu

Product Description

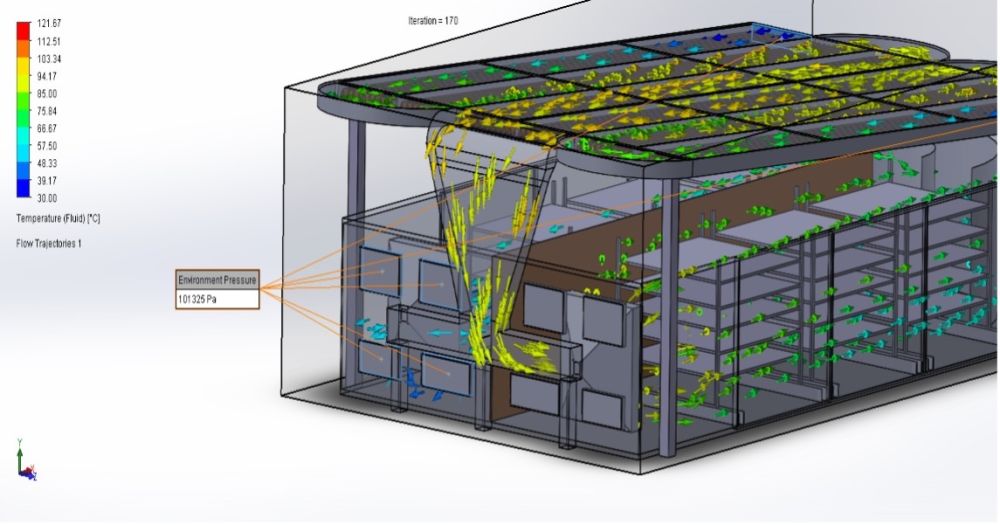

- A hybrid solar drying system was designed, constructed, and tested for the drying of seaweed.

- The drying technique was designed, imposed, and saving time using this technique was 57.9% at the average solar radiation of about 650 W/m2 and an airflow rate of 0.126 kg/s.

- The collector, drying system, and pick-up efficiencies were found about 70, 55, and 75% respectively.

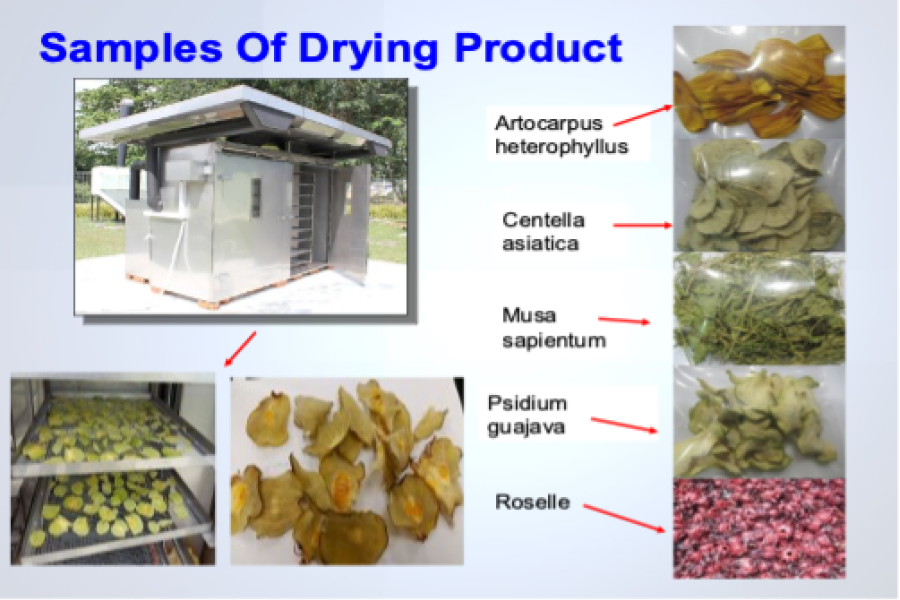

- The study also revealed that the quality of dried seaweed is under the permitted standard of industry carrageenan and has higher quality compared to conventional drying (Platform).

- The SRC produced had physical and chemical properties comparable to the purity specifications of the Philippines Natural Grade Standard (PNGS) which is specifications for semi-refined carrageenan.

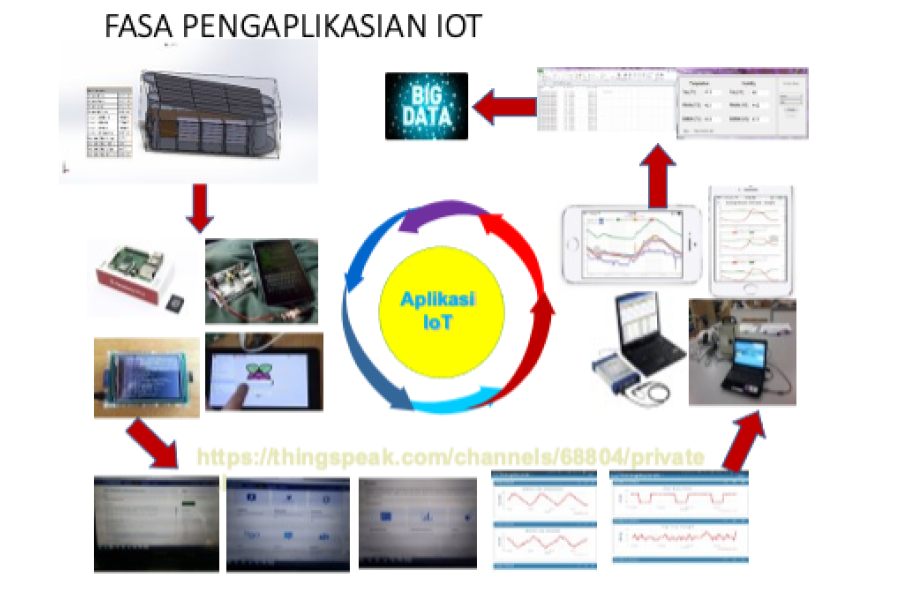

- The Internet of Things (IoT) was also applied to monitor the system and used the recorded data to forecast.

Novelty and Inventiveness

- In the drying process using a solar collector, the main aim is to use the minimum amount of energy for maximum moisture removal for the desired final conditions of the products compared to conventional drying (which will take up to 20 days) of drying (depending on space and size).

- However, a detailed literature review for the present study has shown that there is no information and little data currently exist on the performance of solar drying for seaweed. There was also no research conducted regarding the drier and quality analysis.

- The implementation of IoT to monitor the drying system autonomously also consider the first kind of study for seaweed and can increase the performance of drying, systems, energy, and exergy analyses besides preserving the quality at an optimal level.

Applicability and Benefits

- Easy conversion of natural energy for direct heating and storage results in significant energy savings and better system efficiencies.

- Better product quality with well-controlled drying condition schedules to meet specific production requirements.

- Easy to implement control strategy.

- Higher operating drying temperature compared to a standalone heat pump drying system.

- Social benefits: Environment-friendly product.

- High-value products – High-quality dried products for healthy food and based products.

- Low-cost energy – Drier. Low risk.

- Easy to maintain. Higher demand for cluster programs.

- Economic benefits: Viable business venture (ROI within 8 months).

Commercialization Potential And Industrial Partner

- Market Need To produce a dried product of desired quality, preserve the colour and nutritional value at a minimum cost and maximum throughput by optimizing the design and operating conditions.

- Market Size & Potential Market size (15,000 MT/year) and will benefit our industry to be a top producer of products with high quality while maintaining nutritional value in the food-based product.

- Addressable Market Size & Potential The market is mainly addressed to farmers from the agriculture and aquaculture sectors. Can directly set up and teach the farmer or industry to dry and maintain the quality and create a new market strategy.

- Price Competitiveness More cheaply compared to brands of drier overseas and few private companies in Malaysia.

- Bahagian Jaringan Industri dan Komuniti (BJIM) USM.

- Anais Network Sdn Berhad.

- Masyadir Sdn. Bhd, TERAJU (Prime MInister Office).

- Era Edar Marketing.

- Langkawi Community.

Evidence of Nearest Product Competitor

An overseas companies like Trane, Carrier and York, Rheem, Lennox, Mitsubishi, and Gibson Heat Pump (Source:http://heatpumpdigest.com).

Intellectual Property Status

- Submit for filling (Based on MyIpo patent search, no results for given design and systems)-PI2022006495 – PATENT.

- Submit for Copyright – 8 copyrights.

Status of Invention

Technology Readiness Level 9.

Research Paper

- A. Fudholi, Anicia Q. Hurtado, Mohana Sundaram Muthuvalu, Suhaimi Md. Yasir, Jumat Sulaiman, Mohd Hafidz Ruslan, Majid Khan Bin Majahar Ali, 2017, Post-Harvest Handling of Eucheumatoid Seaweeds, in (Tropical Seaweed Farming Trends, Problems -), Springer , 131-145.

- Majid Khan Bin Majahar Ali, 2022, Extracts of seaweeds used as biostimulants on land and sea cropsdan efficacious, phyconomic, circular blue economy: with special reference to Ascophyllum (brown) and Kappaphycus (red) seaweeds, in (Biostimulants for Crops from Seed Germination to Plant Development A Practical Approach), Elsevier B.V. , 263-288.

- Majid Khan Bin Majahar Ali, 2022, Accurate and Hybrid Regularization - Robust Regression Model in Handling Multicollinearity and Outlier Using 8SC for Big Data, Mathematical Modelling of Engineering Problems, 32:,

- Majid Khan Bin Majahar Ali, 2022, Efficient Model Selection For Moisture Ratio Removal Of Seaweed Using Hybrid Of Sparse And Robust Regression Analysis, Pakistan Journal of Statistics and Operation Research, 21:, 669-681.

- Majid Khan Bin Majahar Ali, 2023, Comparison of Sparse and Robust Regression Techniques in Efficient Model Selection for Moisture Ratio Removal of Seaweed using Solar Drier, Pertanika J. Sci. & Technol., 28(2):, 609-625.