CellinAir Cultivation System: Sustainable Microalgae Production

Assoc. Prof. Ir. Dr. Leo Choe Peng

Assoc. Prof. Dr. Derek Chan Juinn Chieh

Dr. Nazlina Haiza Binti Mohd Yasin

Ms. Yap Jia Xin

Problem Statement

The sustainable of current microalgae cultivation practice is questionable.

- High energy demand: 26 – 2.79 MJ of energy to produce 1 MJ of microalgae biodiesel.

- Large water footprint: 3726 kg of water to produce 1 kg of microalgae biodiesel.

- Costly harvesting: 20–30% of the microalgal biomass cost.

Novelty and Inventiveness

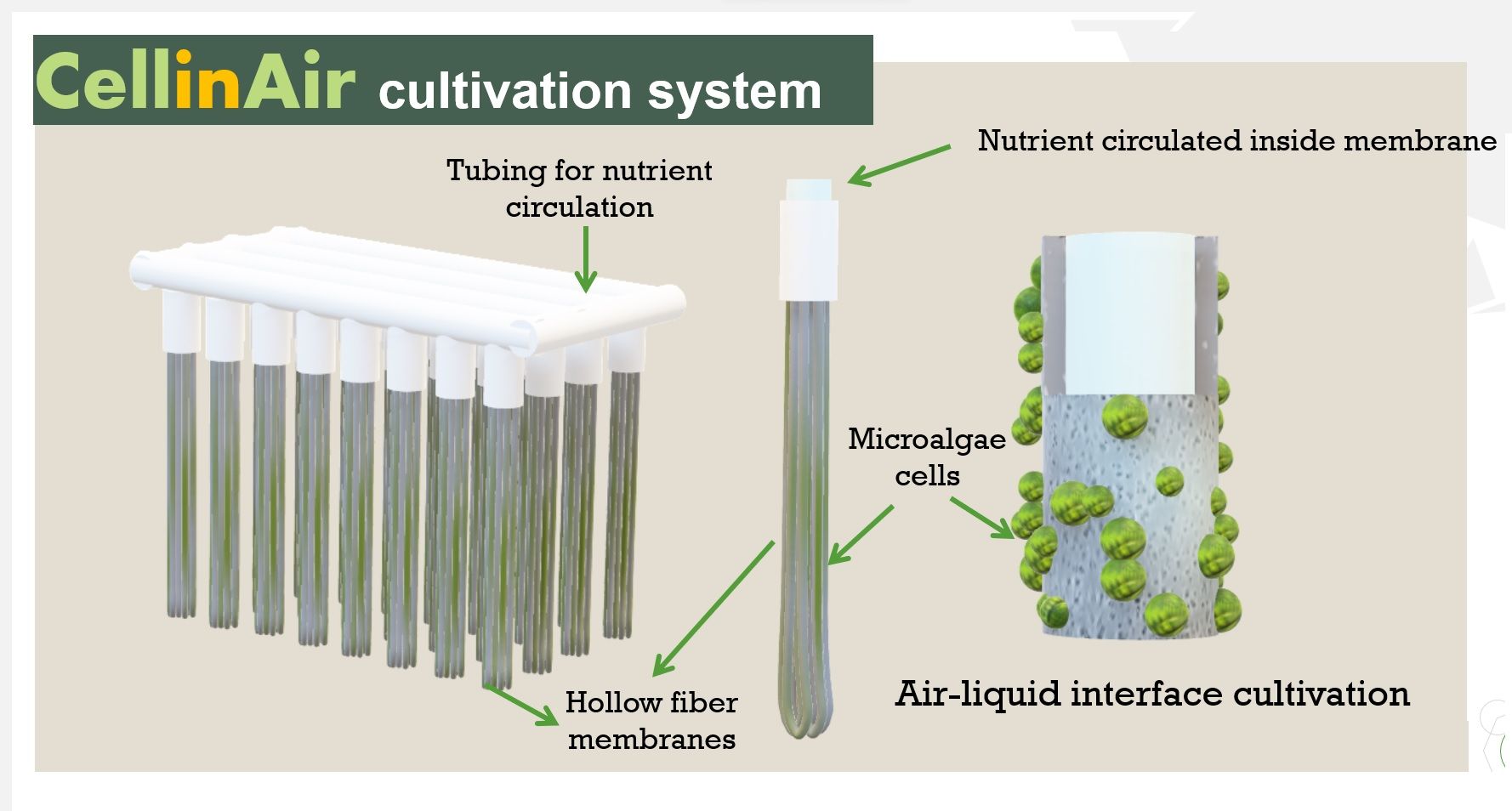

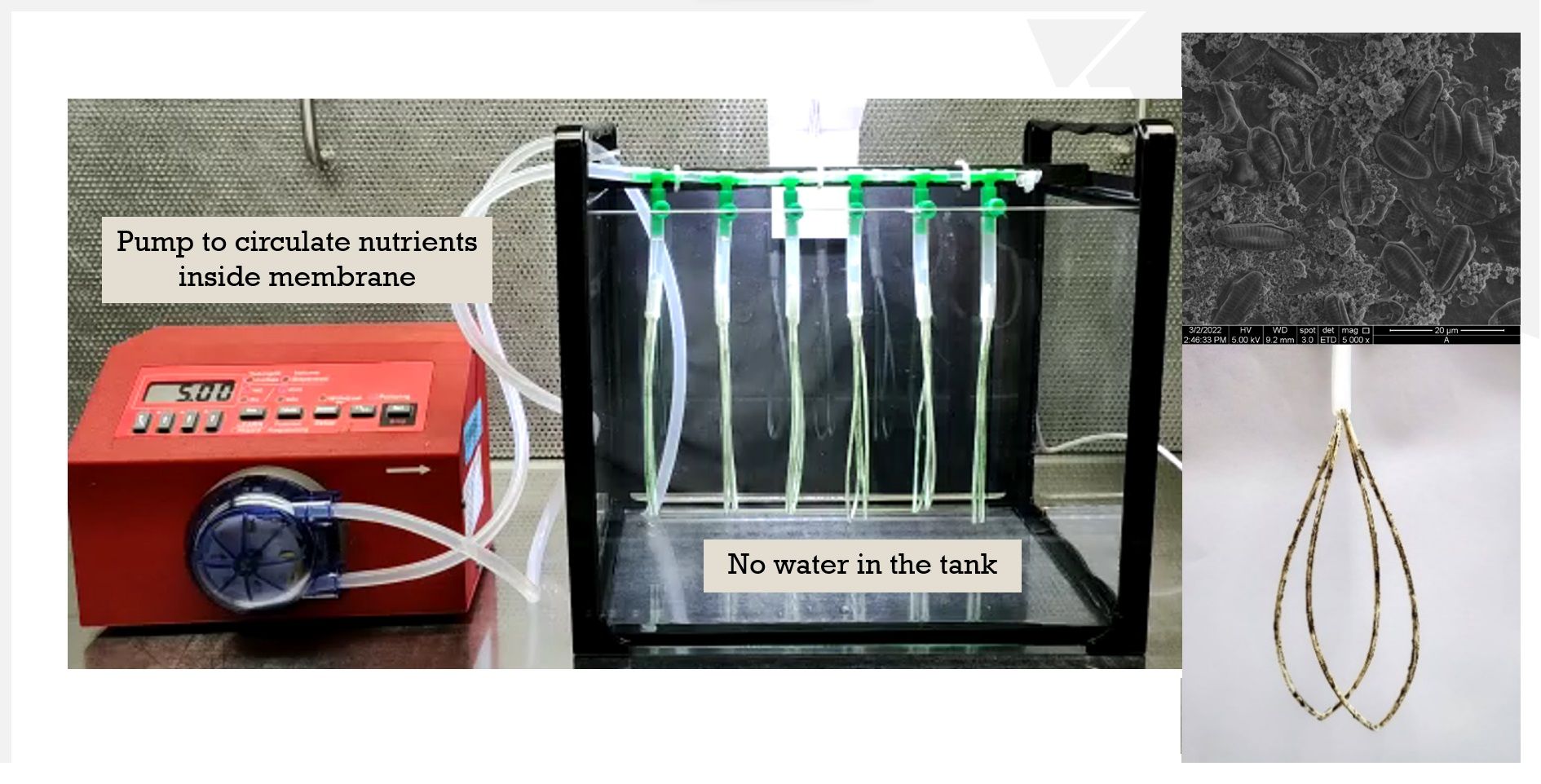

CellinAir Cultivation System allow the microalgae to grow in the air using minimum nutrient. It is air-liquid interface cultivation with with nutrient circulating inside the membrane and microalgae growing on the membrane surface. The advantages of CellinAir cultivation system include:

- Reduce >50% energy by eliminating aeration and dewatering.

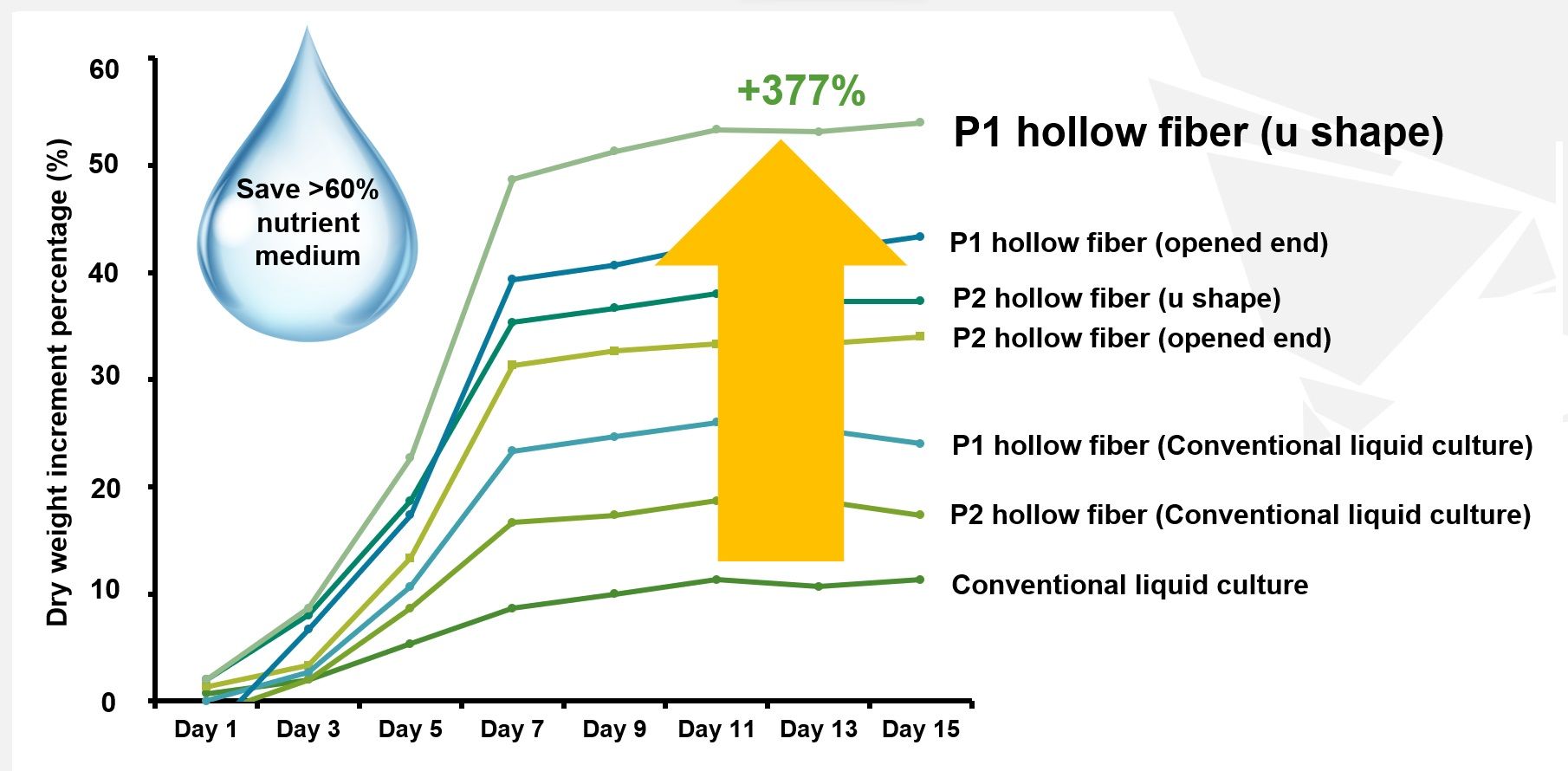

- Save >60% water since cells are not submerged in water.

- Vertical growth allows vertical scale-up with small footprint.

- Promote growth up to 377% in air with direct contact with air and sunlight.

- Easy harvesting through air purge with 70-87% of efficiency.

Applicability and Benefits

- High-value culture scaffold: Biopharmaceutical production, drug delivery; tissue engineering.

- Wastewater treatment: Reduce BOD/COD, nutrient N/P, heavy metals.

- Nutrient recovery: Biofertilizer, Microalgae nanocellulose.

Research Achievement

- 7 ISI Indexed journal papers (5 Q1).

- MRUN and FRGS grants.

- 2 Engineers with MSc. Degree; 2 Ph.D. candidates ongoing.

Commercialization Potential And Industrial Partner

- Microalgae market was estimated to be USD 11.4 billion in 2022.

- Major applications in food and beverages, animal feed, and dietary supplements.

-

Wastewater treatment consultant from Mexico: Tekmann SA de CV.

Intellectual Property Status

Filling Industry Design and Patent on chemically modification of membrane for microalgae adherence.

Status of Invention

Technology Readiness Level 5.

Impact of Innovation

- Knowledge generation through USM-UKM collaboration.

- Community service for local fish farmers.

- Knowledge transfer to wastewater treatment consultant.

- Support “Dasar Bioteknologi Negara 2.0” introduced by MOSTI.