Commercialization of Landfill Leachate Treatment and Simultaneously Produce Bioethanol as A Valuable Product

Assoc. Prof. Dr. Husnul Azan Tajarudin

Dr. Charles Ng Wai Chun

Dr. Siti Baizura Mahat

Miss Ramizah Kamaludin

Dr. Muaz Mohd Zaini Makhtar

Dr. Dayang Haszelinna Abang Ali

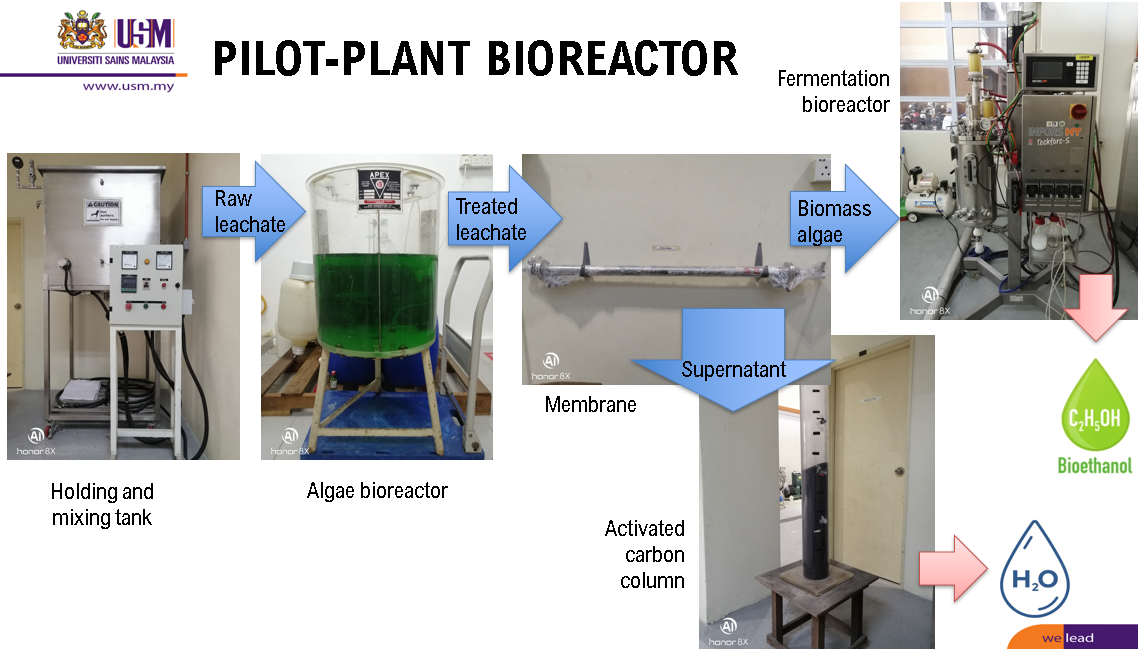

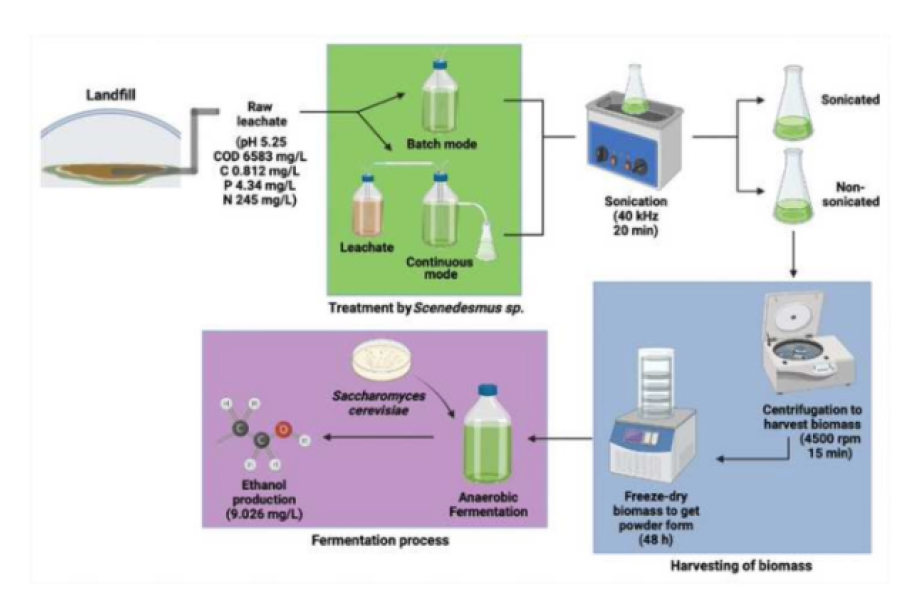

Landfill leachate is a liquid that is produced when water runs through a landfill and picks up dissolved and suspended materials. It is considered a pollutant and must be treated before it can be released into the environment. One potential solution for treating landfill leachate is through the use of algae, which can absorb pollutants and simultaneously produce bioethanol through algae biomass fermentation. The process of using algae for landfill leachate treatment involves creating an algal culture that can thrive in the leachate's specific conditions. Algae absorb pollutants, including nitrogen and phosphorous compounds, through their cells and convert them into biomass. This biomass can then be harvested and used for bioethanol production through yeast fermentation. Algae can grow quickly and can be harvested frequently, allowing for efficient pollutant removal. Additionally, the production of bioethanol through algae biomass fermentation is a sustainable and renewable energy source. This process can also reduce the environmental impact of landfills by decreasing the amount of leachate that needs to be treated and by reducing the need for fossil fuels. This approach not only provides an effective way to treat the leachate, but also generates a valuable product that can be sold to offset the cost of the treatment process.

Problem Statement

- Landfill leachate problem – It is estimated that the total volume of leachate generated from landfills in Malaysia is about 3 million litre/ day, and the quantity of leachate is often more in some countries due to heavy rainfall as Malaysia.

- Leachate can contaminate groundwater and surface water bodies, potentially leading to a range of negative impacts on the environment and public health risks.

- Malaysia does not have a bioethanol industry due to a lack of domestic feedstock; it is infeasible to implement a renewable energy that heavily relies on imported feedstock, despite its benefits.

Applicability and Benefits

- Support Green Technology as our raw material is leachate from landfill. Conversion of leachate into bioethanol can reduce environmental problem due to massive leachate production daily due to Malaysia climate.

- Production of bioethanol from algae biomass fermentation can help to reduce dependence on fossil fuels and promote the use of clean energy sources.

- This technology can help to improve the quality of life for people living near landfills by reducing the risk of exposure to harmful pollutants and chemicals. This, in turn, can help to create a more sustainable and liveable environment for communities near landfills.

Novelty and Inventiveness

- Normally, leachate needs to be treated to avoid contaminations of ground water. Most of the time, the cost for treatment is the main problem, but this project provides low-cost treatment and will give more extra benefit and market value.

- We are using algae-based treatment for leachate is an alternative to conventional biological treatment.

- Our technology has a small footprint, require short operating time.

- This invention produces bioethanol by microbial fermentation of leachate.

- Scenedesmus sp. was used to treat municipal landfill leachate via continuous cultivation modes and algae biomass production for bioethanol production using Saccharomyces cerevisiae.

Status of Invention

Technology Readiness Level 9 – the stage where the system has proven to function successfully and is ready for commercial deployment.

Research Achievement

- Grant - Application of Membrane Bioreactor to Produce Useful Chemicals from Leachate by C. butyricum, USM (RU), RM142,300.00, 1/12/2013-30/11/2016 (Completed- Principal Investigator).

- Grant - Metabolism of Municipal Solid Waste (MSW) Leachate for Acetic and Butyric Acid Conversion by C. butyricum, Kementerian Pengajian Tinggi, RM79,000.00, 1/12/2013-31/5/2016 (Completed-Principal Investigator.

- Publication - Mahmod Sidati Ali Abobaker, Husnul Azan Tajarudin, Abdul Latif Ahmad, Wan Maznah Wan Omar, Charles Ng Wai Chun, 2022. Municipal Landfill Leachate Treatment and Sustainable Ethanol Production: A Biogreen Technology Approach. Microorganisms 2022, 10, 880.

- Publication - Zawawi Daud, Amir Detho, Mohd Arif Rosli, Halizah Awang, Mohd Baharudin Bin Ridzuan & Husnul Azan Tajarudin, 2022. Optimization of Mixing Ratio, Shaking Speed, Contact Time, and pH on Reduction of Chemical Oxygen Demand (COD) and Ammoniacal Nitrogen (NH3-N) in Leachate Treatment, Journal of the Air & Waste Management Association, 72:1, 24-33.

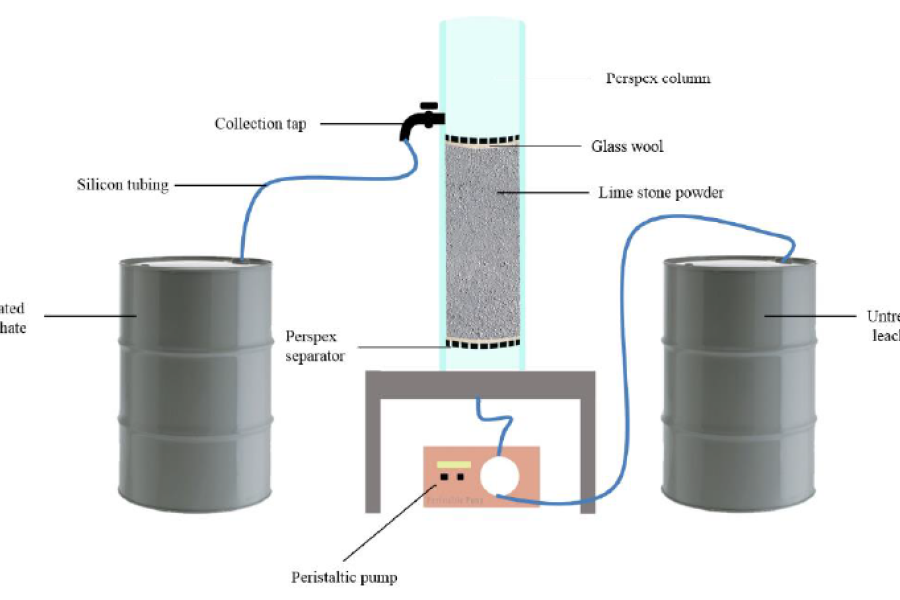

- Publication - Husnul Azan Tajarudin, Amir Talebi, Yasmin Syafikah Razali, Norli Ismail, Mohd Rafatullah, 2020. Selective Adsorption and Recovery of Volatile Fatty Acids from Fermented Landfill Leachate by Activated Carbon Process. Science Of the Total Environment 707 (134533).

- Publication - Zawawi Daud, Amir Detho, Mohd Arif Rosli, Mahmoud Hijab Abubakar, Kamran Ahmed Samo, Nur Faizan Mohammad Rais, Azhar Abdul Halim, Husnul Azan Tajarudin, 2020. Ammoniacal Nitrogen and COD Removal from Stabilized Landfill Leachate Using Granular Activated Carbon and Green Mussel (Perna viridis) Shell Powder As A Composite Adsorbent Desalination And Water Treatment 192, 111-117.

- Publication - Husnul Azan Bin Tajarudin, Mohd Firdaus Bin Othman, Mohd Firdaus Bin Othman, Hamidi Bin Abdul Aziz @ Abdul Rahman, Wan Nadiah Binti Wan Abdullah, Noor Aziah Binti Serri, Mohd Redzwan Bin Tamat, 2017. Bioconversion of Leachate to Acetic and Butyric Acid by Clostridium butyricum NCIMB 7423 In Membrane Fermentor, Journal of Pertanika, 25:, 39-48.

- Chapter In Books - Husnul Azan Tajarudin, Mohd Redzwan Tamat, Mohd Firdaus Othman, Noor Aziah Serri. Chapter: Biological Treatment Technology for Landfill Leachate (2016). Control and Treatment of Landfill Leachate for Sanitary Waste Disposal. IGI Book.

- Chapter In Books - Husnul Azan Bin Tajarudin, Noor Aziah Binti Serri, Mohd Firdaus Bin Othman , Mohd Redzwan Bin Tamat, 2016, Biological Technology for Landfill Leachate, In (Control and Treatment of Landfill Leachate for Sanitary Waste Disposal), Igi Publisher, 219.

- Talents

- Master Graduated: 4 students.

- PhD Graduated: 2 students.

- RO: 2 officers.

- Postdoc: 1 researcher.

Commercialization Potential And Industrial Partner

- High yield productivity, low-cost and environmentally friendly.

- Demand for bioethanol as a clean energy source. The growth of the biofuels industry, particularly in regions with favourable policies and incentives, will help to drive demand for bioethanol and support the growth of this market. Additionally, the increasing awareness of the environmental benefits of using biofuels as a cleaner alternative to fossil fuels is also likely to increase demand for bioethanol in the future.

- Our tech can decrease price for leachate treatment, currently is RM55/m3

- Price market worldwide for bioethanol is $1.16 to $1.44 per gallon ~ $0.38/ Litre (RM1.52 / Litre), but our product (bioethanol from fermented leachate) only cost RM 0.22 / Litre.

- On-going commercialization with Solid Waste Management (SW Corp).

Intellectual Property Status

- 2022 PATENT GRANTED: A Process for The Production of Acetic Acid and Butyric Acid (MY-193503-A/ PI 2015704214).

- 2 Copyright:

- A Conversion Leachate to Acetic and Butyric Acid, LY2018005377, 02/11/2018.

- Separation Acetic and Butyric Acid by Activated Carbon, LY2018005378, 02/11/2018.

Impact of Innovation

- Environmental: This approach provides an effective way to treat landfill leachate, reducing the risk of pollutants and harmful chemicals leaching into the environment. Algae are highly efficient at removing pollutants from water and can be used to treat a wide variety of contaminants, including heavy metals and nitrogen compounds. Additionally, algae can be grown in a closed-loop system, which reduces the need for large quantities of water and eliminates the need for chemical treatments.

- Economic: The production of bioethanol from algae biomass can provide a new source of revenue for landfill operators and help to offset the cost of the leachate treatment process. Additionally, the development of this technology can create jobs in the fields of engineering, construction, and operations, which can have a positive impact on local economies.

- Academia: Academia, research institutions and universities can help to develop and improve the technology, by providing knowledge and expertise, as well as contributing to the education and training of students in the field. They can also help to identify new opportunities for the technology and support its development through research and development programs.

- Civil Society: The commercialization of this technology can help to improve the quality of life for people living near landfills by reducing the risk of exposure to harmful pollutants and chemicals. Additionally, the production of bioethanol from algae biomass can help to reduce dependence on fossil fuels and promote the use of clean energy sources.

- Government: This technology can help to meet environmental regulations and standards for treating and disposing of landfill leachate. Additionally, the development of this technology can help to promote the growth of the biofuels industry and support the government's goals for reducing greenhouse gas emissions and align with Sustainable Development Goals (SDGs).